Why are ZLD processes on the rise?

Access to water is no longer assured. Cape Town narrowly averted “Day Zero” amid intense public scrutiny during a 2018 drought. In June 2019, the 11 million residents of Chennai, India, endured a day without drinking water, and in 2020, the towns of Stanthorpe and Clifton in Queensland, Australia, both experienced water depletion. These incidents are not isolated and are projected to escalate as climate change effects intensify.

When faced with systemic risks to economic growth and public health, the economic implications of enforcing stricter water treatment and recycling regulations far outweigh maintaining the status quo. Given that industries account for about 20% of global freshwater consumption—and are typically well-funded compared to other consumers—governments are increasingly tightening controls on industrial wastewater disposal. In addition to bolstering water reserves, limitations on wastewater disposal offer the added benefit of safeguarding aquatic environments.

At the pinnacle of wastewater management is Zero Liquid Discharge (ZLD), a method that eradicates all liquid waste exiting an industrial facility, albeit with the highest associated capital and operational costs.

As detailed in “The Global Rise of Zero Liquid Discharge for Wastewater Management: Drivers, Technologies, and Future Directions” by Elimelech and colleagues, countries leading the charge in implementing ZLD regulations include the United States, China, and India. While the power sectors dominate ZLD markets in the United States and China, the textile industry emerges as a key driver in India’s adoption of ZLD practices.

The potential for lowering the CAPEX and OPEX cost of ZLD

Traditional ZLD processes are based on water evaporation, including multistage evaporative distillation (MED), multistage flash distillation (MSF), crystallizers and evaporation ponds. However, MED, MSF and crystallizers suffer from high energy consumption due to the use of electricity or fossil fuel. In addition, the construction of corrosion resistant containers in these brine concentrators and crystallizers is costly and brings the capital cost high. On the other hand, evaporation ponds demand extensive land space, and their evaporation efficiency is generally low.

Addressing the challenges of high energy demand, high capital cost, and large footprint, membrane technologies have demonstrated great potential. This is attributed to their low energy demand, excellent corrosion resistance, and compact design. A few membrane technologies have been investigated, including osmotically assisted reverse osmosis (OARO), membrane distillation (MD), electrodialysis (ED), and forward osmosis (FO).

Few technologies, if any, have targeted eliminating the need for evaporators. The remainder of this article will focus on how SideStroem’s nano-selective forward osmosis technology (FOns) can potentially replace evaporators in greenfield zero liquid discharge systems.

SideStroem Water Technologies (Mark)

SideStroem Water Technologies Pte. Ltd. is a Singapore-based water tech company obsessed with efficiency in resource recovery from industrial wastewater and industrial processes.

We are reinventing resource recovery through a technology platform that enables selective recovery of water and salt, which decreases energy consumption of zero liquid discharge systems by up to 55%.

In addition, our technology platform will enable gentle extraction of inhibitory biproducts from fermentation broths, which unlocks continuous fermentation and a reduction of unit production costs of up to 80%.

Our beachhead market is India’s textile industry where Zero Liquid Discharge (ZLD) has become the gold standard in wastewater treatment.

Nano-selective forward osmosis (FOns) can improve ZLD processes

SideStroem recognizes that forward osmosis membrane technologies hold several advantages over traditional pressure driven membrane technologies and we are the only company developing novel nano-selective forward osmosis (FOns) technology tailored to selectively recover & recycle both water and salts from wastewater streams in textile and tannery industries. Forward osmosis doesn’t require external pressure; its energy consumption can be significantly lower than pressure-driven processes; it has lower fouling tendency, and it is suitable for pressure- or heat-sensitive solutions. SideStroem’s FOns technology employs special membranes, that enable simultaneous recovery of both water and valuable solutes from wastewater streams.

Conventional ZLD systems have three stages of treatment, namely, primary, secondary, and tertiary treatment. The tertiary treatment involves extensive pre-treatment and evaporator, which is energy intensive.

SideStroem’s FOns technology has the potential to eliminate the entire tertiary treatment units, and provide a simplified solution for resource recovery of existing and new ZLD systems. This unlocks CAPEX & OPEX savings of more than 50%.

FOns membrane concept

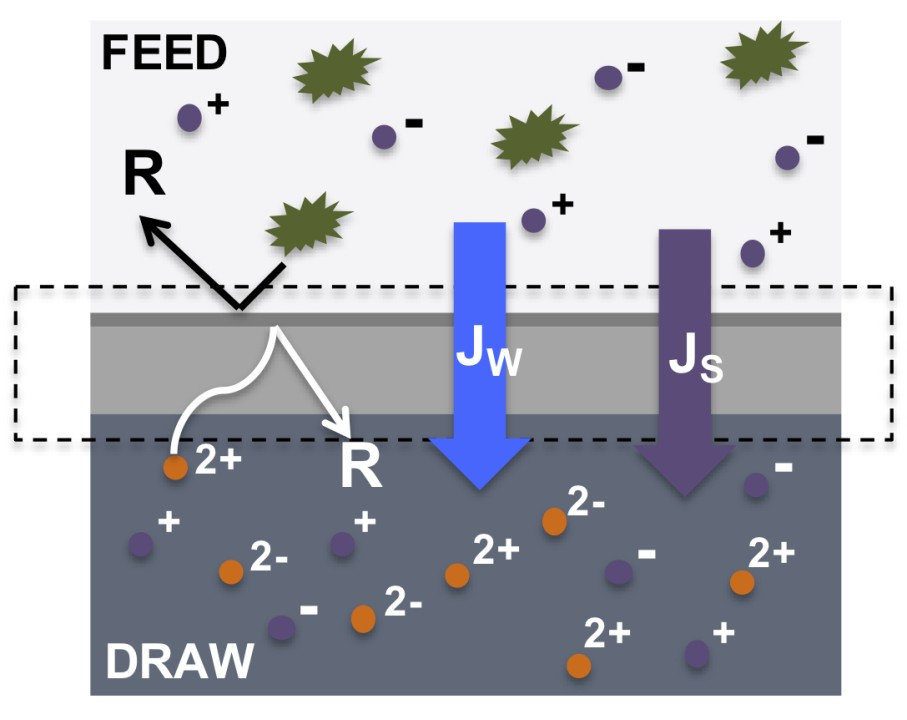

Conventional FO membranes are designed to extract water from feed streams while rejecting virtually all other compounds. These membranes feature reverse osmosis-type (RO-type) rejection layers, categorizing them as RO-type FO membranes. The primary drawbacks of this membrane type include low water flux and non-selectivity to ions.

In contrast, NF membranes exhibit increased water permeability and the ability to separate monovalent ions from wastewater solutions, offering opportunities for resource recovery. However, conventional NF membranes perform poorly under FO operation due to compact support layers and significant internal concentration polarization (ICP), making them unsuitable for FO applications.

Recognizing these challenges, Sidestroem has innovatively combined the strengths of FO and NF membranes to create a unique nano-selective FO membrane. This technology integrates the best features of NF and FO, providing low fouling, precise selection, and high operational stability. It facilitates the selective recovery and recycling of both water and valuable salts from wastewater streams. Our technology offers a significant advantage in reducing operational expenses for wastewater treatment while increasing the yield of recovered resources—an improvement over current treatment methods.

What’s next?

SideStroem recognises that in the current conservative landscape of the water industry, the commercialization of forward osmosis technologies involves strategically pinpointing applications characterized by significant customer challenges—the low-hanging fruits. These are areas where existing technologies are either inapplicable, highly inefficient, or excessively costly.

Hence, reducing the OPEX & CAPEX costs of zero liquid discharge systems represents an ideal opportunity both from a commercial and environmental point of view.

We welcome water system integrators and industrial end users to contact us for more information about piloting and collaboration opportunities.