By Geza Csornyei, Attila Farkas, Tamas Kovari, Bernadett Lemaire, Jozsef Neer, Budapest Waterworks

Abstract:-

In the past few decades, global population growth has been dominated by an increasing urban population. Maintaining urban hygiene and healthy water resources a major challenge to many countries around the world. Wastewater treatment approaches vary from the conventional centralized systems to the onsite decentralized systems. While in dispersed households decentralized water treatment solutions are promoted in order to economize the investment costs of the sewer system, for more densely populated areas centralized treatment represents a cost-effective solution. Centralized treatment solutions are usually robust and have high treatment efficiencies. The treatment plants are commonly located far away from human settlements to avoid possible odorous and esthetic complaints. Smaller number of treatment plants are easier to manage and their reduced footprint represent higher sustainability. The relatively higher investment and energy costs of centralized treatment can be balanced by the implementation of energy efficient technologies.

Introduction :-

Budapest Waterworks Private Company Limited by Shares is the operating company of the Budapest Central Wastewater Treatment Plant (BCWWTP) in Hungary, which is the largest sewage treatment facility in the Central European region. The plant was designed for 1.6 million PE (BOD5), with an average biological treatment capacity of 350,000 m3 /d, that can go up to 525,000 m3 /d in peak hours, which is equivalent to Budapest’s total daily sewage production. The construction of this plant was co-financed by the European Union, being a part of the ‘Living Danube Project’, aiming to ameliorate the water quality of the Danube River, the receiving body of the Plant’s treated water. The applied technology of BCWWTP is a conventional activated sludge (CAS) treatment, where all technological structures are covered, ventilated and the foul air is entirely treated. By creating green rooftops on the technological buildings 70% of green surface was achieved on the Plant to fit in the urban environment. It also permits to reduce energy costs by its natural insulation capacity and by absorbing storm water, which enabled to avoid the installation of complex drainage systems. The footprint of the Plant was decreased by utilizing enhanced lamellar pre-settlers followed by multi-storey basins built on the top of each other. Through the anaerobic thermophilic digestion of the mixture of the obtained primary sludge and surplus activated sludge, biogas is produced which is used to generate electricity and heat. The Plant’s combined heat and power (CHP) cogeneration units ensure around 60% of the Plant’s daily 100 MWh energy need, in a yearly average. The stabilized dewatered sludge (62,000 tons/year) is currently used for landfilling. However, as a result of the highly efficient pathogenic elimination capacity of thermophilic digestion, (which also inactivates COVID-19 virus) it meets all the criteria of a ‘Class A’ sludge, known as ‘exceptional’ quality. Thus, it has a high potential for agricultural use.

Thermophilic anaerobic digestion:-

Throughout the centralized wastewater treatment, the transport and the storage of different kinds of by-products represent a major part of the operation costs. Handling those by-products raised questions from the early days of wastewater treatment however it became a serious problem only from the last couple of decades since numerous high capacity treatment plants emerged all over the word. At present, large wastewater treatment plants, with more than 1 million PE capacity, produce 150 – 200 tons of sludge daily, not mentioning other products such as grit, or screening waste. Parallel with the development of modern wastewater treatment, sludge treatment also evolved. Although the first known aerobic digester was built in Bombay in 1895 and was used for gas recovery in England by the end of the 1800s, it became wildly available only from the last 20 – 30 years all over the world, with Denmark in the leading role of the development. Sludge digestion has three main advantages which are very profitable for both the wastewater treatment plant itself and for the local community. Digestion reduces the overall volume of the sludge that helps lowering the transportation and storage costs. It also reduces the number of pathogenic bacteria in the waste sewage sludge which minimizes the risk of epidemic among the local population. Finally, a well operated digester produces a great amount of biogas that can be used as green energy for the plant itself or can be sold for other consumers. In the early days the focus was on sludge reduction and stabilization, but nowadays when there is an ever growing demand for green energy, biogas production became the main target for most of the operators.

Digestion solution

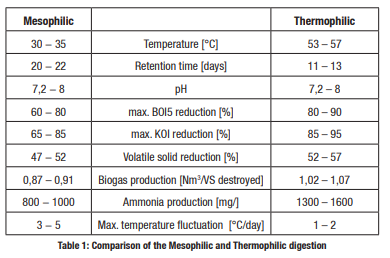

Sludge digestion can be aerobic or anaerobic, which means the digestion takes place with the presence or the absence of oxygen. In most cases the digestion is anaerobic, which is in the focus of this article. During the anaerobic digestion the presence of oxygen is not only unnecessary, but downright an inhibitor for the process. For sludge digestion two main types of digestion method exist, Mesophilic Anaerobic Digestion and Thermophilic Anaerobic Digestion. The two processes are very similar, only the regulating parameters are different. Both methods need a closed, heated and continuously mixed digester tank, the difference is the operating temperature and the retention time. The most widely used type is the Mesophilic one, but recently the number of Thermophilic digesters have been increasing. If we compare the two methods, we can find advantages and disadvantages related to both processes, but nowadays the advantages of the Thermophilic type became more and more important and in some cases it starts to outshine the Mesophilic one.

Thermophilic Anaerobic Digestion in general:-

As mentioned before, the number of Thermophilic digesters is growing all around the world, mostly because they can drastically reduce the investment costs and they have a higher biogas output. Thanks to the short retention time, the digester volume is reduced about 40 – 50%, which can’t be overlooked, since in case of a Mesophilic system the construction cost of the digester tower can add up to half of the total cost of the digester including all the necessary equipment. It is also important, that the Thermophilic system works with a higher efficiency so the biogas output is 20% better than that of the Mesophilic one. Another advantage of the Thermophilic digesters that they have higher volatile solid reduction capacity, which is the key factor of the chemical consumption during the dewatering phase. On the other hand it needs higher operator discipline, because the Thermophilic digesters are sensitive to sudden parameter change. Furthermore the ammonia content of the leachate water requires additional energy input in the main treatment line, but with tertiary treatment these additional costs can be reduced significantly. Experiences in the Budapest Central Wastewater Treatment Plant The Budapest Central Wastewater Treatment Plant has tree Thermophilic Anaerobic Digesters with the overall volume of 18,168 m3 . These digesters are able to accept 88 tons of dried solid each day. In comparison, with Mesophilic technology for the same quantity of sludge the required digester volume would be around 33,000 m3 . The inlet sludge is a mixture of primary and secondary sludge, in our experiences the rate of the two types can vary in a wide range without any significant drop in the quantity of produced biogas. The produced biogas rate from the degraded sludge is also very high. With adequate residual time even 1.1 – 1.2 Nm3 of biogas can be produced from each kilogram of degraded dried solid. Furthermore, the overall sludge degradation is also high. In our experiences the total sludge loss during the digestion is 37.5%, which means, that the sludge that we need to transport and dispose of is also 37.5% less. The quality of the biogas remains also stable even in extreme inlet conditions. The methane content stays between 59 and 62%, with low H2S formation. The H2S level usually stays below 80 ppm, without any additional treatment, that value is less than the half of the level that is permissible for the operation of the biogas engines.

The quality of the outlet sludge is also excellent. Due to the higher operation temperature, which take place between 55 and 56 C for 12 days, the pathogenic removal is much higher than it would be with Mesophilic digestion. Under these conditions the outlet sludge becomes category “A”, without any further treatment, which makes the sludge suitable for agricultural purposes. Despite of the higher operational temperature, the system energy balance is also excellent. The heat that the biogas engines produce during their operation is enough in most of the year to maintain the digesters at their adequate temperatures. Only in winter time, when both air and sludge temperature drops, is additional heat source required. To ensure the excess heat demand of the winter period three boilers are installed. At the Budapest Central Wastewater Treatment Plant three gas engines are in operation in order to provide electricity and heat, each with a capacity of 1.4 MW. That covers 60% of the Plant’s daily 100 MWh energy need, in a yearly average. The continuous operation of these combined heat and power (CHP) cogeneration units require adequate engineering and maintenance skills, which are ensured by Budapest Waterworks. Figure 6: Biogas engine at BCWWTP The continuous supply of biogas to the cogeneration units needs careful preparation. To elongate the lifetime of the gas engines and the boilers, the purification of the biogas is inevitable. Thus, at Budapest Central Wastewater Treatment Plant a multi-step biogas purification system is used. The biogas purification starts immediately after its generation by a wet scrubber, where the larger contaminants are eliminated from the gas phase. The biogas generated through thermophilic digestion has an increased humidity, thus the second step of the gas purification is the condensation. This takes place in a high-efficiency dehumidifier installed preceding to the gas storage units. Finally the biogas is conducted through active carbon filters to eliminate the siloxane derivative molecules of the biogas. The biogas arrives purified and compressed from the point of generation (25 mBar) to the point of consumption (150 mBar) of the gas engines and the boilers.

Summary

The operation of BCWWTP has been designed to have a large degree of redundancy and safety to ensure that the mentioned objectives can be met with a minimum of operator intervention and a high degree of reliability. For Budapest Waterworks sustainable development and environmental protection are important, thus, a project was launched in order to discharge the produced biogas to the natural gas grid of Budapest. Currently, the project is in start-up phase and it requires the implementation of a supplementary purifying step to achieve a gas quality equal to natural gas. This would decrease the operating costs of the Plant at the same time it would contribute to the green energy supply of Hungary. The operation and development of the facility requires highly educated experts and engineering staff. Budapest Waterworks, as the water utility operator of the Hungarian capital has more than 150 years of experience in operating water and waste-water assets. We have been active in international markets as well for almost 20 years in construction and consultancy projects where we can support our partners with the technological and managerial knowledge we have gathered.