By Vinay Chataraju, Co-Founder & Head Business, Kritsnam Technologies Pvt. Ltd.

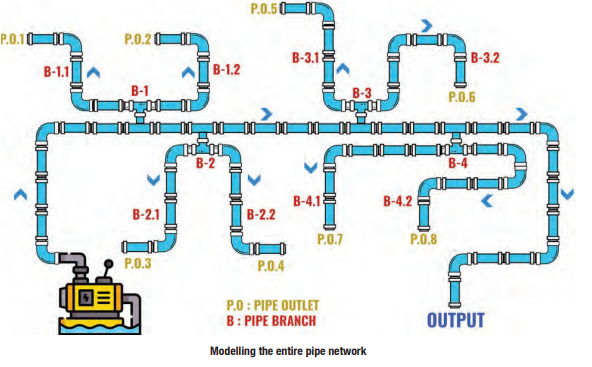

With the rapidly depleting groundwater table, NGT has passed orders for strong regulations on effective usage of groundwater especially targeting bulk water users such as industrial, commercial and bulk housing. After much discussion, Central Ground Water Authority (CGWA) released a gazette notification on 24-Sep-2020 with guidelines for groundwater extraction for industrial and infrastructure projects. Though the guidelines exempted projects drawing less than 10KLD from taking an NOC, there has been increasing pressure on CGWA not to dilute the regulations. The current guidelines clearly indicate the regulations are going towards efficient and sustainable usage of groundwater for commercial purposes. Some of the outstanding moves in the current guidelines are 1) Annual Water Auditing for industries consuming more than 100KLD 2) Industries have to adopt suitable methods to reduce water consumption by 20% in 3 years 3) Installation of tamper proof flow meters with telemetry at groundwater abstraction structures 4) Hydrogeological and impact assessment report have to be submitted for projects drawing more than 100KLD in OCS areas. Though it may sound like a big deal for industries to reduce water consumption by 20% in 3 years, our experience says that it is practically possible to reduce the consumption by 20% in 3 years just by disciplined and informed usage of water without changing the major infrastructure. Many manufacturers/industries don’t have the information they need to manage the water that flows through their processes—information that is critical for improving productivity. Technology providers are starting to develop products that can help these industrial companies improve the way they track their water usage and monitor their progress. Until now water management in India is majorly a guesswork based on heuristics. Most of the bulk water users including government departments are yet to adopt appropriate scientific methodologies for managing fresh water. The future is data driven intelligent decision making to support water security and sustainability. Collectively as a nation, starting from household water management to managing large water systems such as rivers and reservoirs should increasingly adopt data-driven water resources management techniques for effective use of our precious freshwater resources. We at Kritsnam Technologies have engaged in extensive R&D for the past 7 years to solve our local problems in deployments, measurements and data usage. We have developed a suite of reliable IoT enabled instruments to remotely track the water levels and flow. The real-time level and flow data from these instruments is easily accessible to the users, right at their fingertips through SMS, WhatsApp, Web & Mobile apps. Continuous internal water auditing system:- Why should industries opt for Continuous internal water auditing system? 8 Potential to reduce up to 20% fresh water extraction in 2-3 years (As per CGWA guidelines) 8 Monitor the actual cost of water associated Segregating the batch processes for an industry type Estimating the optimal water requirements for each process and sub processes Testing the re-usability of the output water from each process exit 8 pH 8 Electric Conductivity 8 Dissolved Oxygen 8 Turbidity 8 Anions 8 Cations 8 Total pump working hours every day 8 Identifying process inefficiencies 8 Identifying the pump wear outs 8 Identifying the leakages 8 Trends of water footprint 8 Water demand forecasts 8 Real time alerts & notifications 8 Electricity bill forecaste Integration with ERP and other dashboards Ultrasonic flowmeters and level meters to track water distribution continuously and transmit the data online Alerts on WhatsApp/SMS Dashboard with graphs . with the product unit economics – pumping, storage, treatment 8 Track the inefficiencies in water use, reduce water wastage and improve organically 8 Regulate the load on ETP’s 8 Improve batch to batch product uniformity and product quality 8 Be ready for ISO 46001 standard 8 Prepare for upcoming stringent regulations on water usage What are the steps involved in Continuous live internal water auditing system? 8 Digitising the pipeline network from source till reject 8 Identifying the different processes from fresh water input and waste water output 8 Benchmarking the average water requirement per process 8 Analysing the output water quality for every process 8 Indicating the strategic representative points to measure the water quantity in real-time 8 Installation of flowmeters in the pipelines and level meters in the storage tanks 8 Calculation of water usage per process and deriving advisories for water reduction 8 Daily reports on total water usage and water costs, per process water usage and costs, identification of processes consuming more water than required etc. 8 Weekly, monthly and yearly reports on water usage patterns