By Amit K., Prabhat R., Pushkar S., Sanjeev G., Hiten M., Water application and product development centre, Grasim Industries Ltd., Bharuch, Gujarat, India

Large quantity of water is generated during crude oil exploration called as ‘Produced water’ (PW). The produced water contains oil mostly in emulsified form along with a lot of suspended impurities, making it one of the most difficult to treat. With the increase in emphasis of recycling of water in oil exploration units, the treated wastewater is used as Well Injection Water and the prime challenge remains in making the water fit for Well Injection or Discharge. The direct injection/disposal of produced water to the well/environment may cause disturbances in well/ ecology. Therefore, treatment of produced water prior to injection/ disposal is very essential.

Physical and chemical methods such as adsorption coagulation & flocculation, filtration technique and advanced oxidation processes have been well evaluated but still industry faces issues for handling of oil rich wastewater. Treatment of oil containing wastewater OR Produced water (PW) is one of the most important environmental problems throughout the world as the oil (as O & G) in the oil industry i.e. oil exploration and production, oil refining, oil storage, transportation and petrochemical industries in the production process generate lot of oily wastewater. Produced water is one which is produced as byproduct in large quantity during production of oil and gas from oil well. This water contains ample amount of free & emulsified oil, grease, dissolved & suspended solid. Typically, ~100-1000 ppm oil & grease present (depending upon oil well conditions) in produced water in free, emulsified & dissolved form. Discharging of this water may pollute surface and underground water as well as soil. As per environmental regulation, max. 10 ppm of oil and grease is permitted in discharge water. Few industries also re-inject produced water in oil well after removing oil and suspended solids to enhance oil well recovery.

The organic nature and constituents of the wastewater varies with the type of crude i.e. light, medium and heavy, sour and sweet. Produced water contain emulsified oil which remain recalcitrant to biological treatment and hampers bioprocess by fouling the microorganisms. Organic toxic waste (oil and grease (O&G)) causes ecology damages for aquatic organism, plant, animal, and equally, mutagenic and carcinogenic for human being. Presented case study focuses on improvement in treatment of oil rich wastewater and meeting the quality of treated wastewater for recycling using specialty solution as de-emulsifier and coagulating aid

Treatment of oil containing wastewater and challenges:

The wastewater from process contain oil in different forms along with suspended solids, oil may be free, emulsified and dissolved form. Application of technique widely depends on nature of oil being separated and can be classified based on size of droplet of oil in the medium. Free oil can be separated using API separator whereas Tilted plate interceptor (TPI) can be used for separation of dispersed oil. Techniques like coagulation, adsorption, filtration etc. are used for removal of emulsified and soluble oil from the wastewater but have limitation to ensure low oil content in treated water.

Grasim dual chemical solution has been found capable to handle all forms of oil and separate it from water to ensure oil content less than 10 ppm in treated water with excellent clarity by removal of suspended and colloidal impurities. Grasim Specialty solution for separation of emulsified oil from produced water: Removal of emulsified oil is critical for the overall wellbeing of wastewater treatment plant and the same remains the focal point of operations. Oil content greater than 10 ppm is not acceptable for discharge as per CPCB guidelines. Also, high oil content and Suspended matter prevents use of water for reuse. Specialty solution VYTAL 2810 was developed for efficient separation of oil which deemulsifies oil and separates it from wastewater, it also neutralizes the charge on colloidal suspended matter leading to de stabilization of suspended material. Wastewater from oil processing industry contains oil-water emulsion along with colloidal and suspended matter. Vytal 2810 de-emulsify (demulsifies) oil and separate (separates) it from wastewater, it also neutralizes the charge on colloidal matter leading to de-stabilization of suspended material. The neutralized particles then form agglomerates by coming together. The agglomerates thus formed can be removed by addition of a high molecular weight flocculent which will float (DAF/IGF process) or settle at the bottom of the clarifier. Produced water from different oil and gas exploration region were evaluated with Vytal 2810 followed by Vytal A971. Required customization were made to make it suitable for all types of oil

It is quite evident from the table that performance of Vytal 2810 was effective for different types of produced water although chemical dosages varied with nature of crude oil source. Other advantages observed were as following:

8 Dual chemical system hence eases operations 8 Effective at low dosages against presently used conventional chemicals

8 Efficient removal of oil and excellent clarity of treated water 8 Stable at high temperature (80-90 C) for treatment of hot wastewater streams without effecting treatment efficiency

8 Can work for oil concentration from few ppm to percentage level without compromising with treated water quality

8 Vytal 2810 has robust performance against all types of wastewater irrespective of source of oil

Produced water treatment

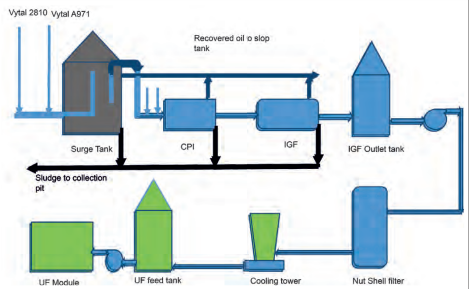

in Western Oil-Field in India – Case study Present case study focuses on treatment of oil in effluent generated at a Group Gathering Station (GGS) of an oil exploration unit in western Indian oil-field. Wastewater collected from the process was pumped to ETP where Alum and de-oiling polymer (DOP) were being added (Figure 3). This Effluent treatment plant consisted of Surge tank, CPI, induced gas flotation (IGF), nutshell filter (NSF) & Ultrafiltration Unit. The treated water from this ETP is used for injection into the Oil wells and must meet the norms for TSS, Turbidity and Oil & Grease content in treated water prior to discharge to Well. Plant management wanted to improve the Oil & Grease content, TSS & Turbidity in treated water. In the present case, the GGS was partially able to meet discharge norms for Oil content in wastewater due to fluctuations in treated water parameters based on quality of raw wastewater. It was understood that the oil was mainly in emulsified form indicating poor performance of existing chemical treatment (Non-ferric alum & DOP). The Dual Chemical System Comprising of VYTAL 2810 & VYTAL A971 has the capability to separate emulsified oil efficiently leading to better performance of DAF/IGF. Vytal 2810 can be used as primary treatment of wastewater and can be added prior to Gas flotation (DAF/IGF) unit under flash mixing followed by addition of high molecular weight polymer. Both the chemicals were added at the existing dosing point of ETP i.e inlet to surge tank. Dosage of existing chemicals Alum and DOP was 50-60 ppm and 20-30 ppm, respectively whereas dosage of dual chemical Vytal 2810 and Vytal A971 was 20-25 ppm and 2-3 ppm, respectively. Dosage of proposed chemicals was only ~30% of the existing treatment. The treated water must contain TSS and Oil less than 100 & 10 ppm, respectively for disposal of treated water by re-injection in abandoned well below a depth of 1000 meters. Treated water met the requirement very well with proposed treatment where oil content in treated water.

Conclusion: Raw produced water is commonly regarded as a high-volume toxic waste but can be beneficial to humans if properly managed. The treatment of produced water is very important due to legislation and environmental concerns. With detailed studies of general compositions of produced water and strong understanding of coagulation and flocculants chemistry, ABWAPDC team has come up with dual chemical treatment system which has following advantages against conventional and inefficient technologie

s 8 VYTAL 2810 & VYTAL A971 (dual system) is effective and economical due to lower chemical doses consumption.

8 Dual system shows good reduction in Turbidity, TSS and Oil & Grease and very well meeting norms of discharge.

8 Reduction in Turbidity, TSS and Oil & Grease helps in improving the Nutshell Filter Life by reducing load and back-wash frequency on a long-term basis. 8 Improved Flocs size has also results in efficient Sludge removal with the Belt Filter Press.

8 Improved performance of Belt Filter Press eliminates need of Sludge recirculation back to the system and reduces operation cost