By Ashish Chauhan, Asst. Manager (Process & Project), Lords Chloro Alkali ltd.

In recent few years water scarcity is emerging problem in the world. Now days not only in Asian continent but also in European countries like England, Finland faces drought like scenario. Availability of Portable is limited and uneven rainfall made condition more badly.

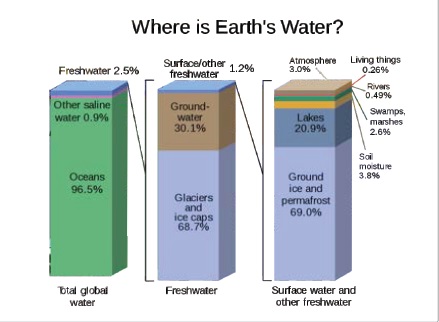

As per Data of water availability around 71% of earth surface is covered with water. In which only 2.5 % is only fresh water out of which only 31% available for us.

In recent years many initiative has been taken by industries. A very common known techniques are listed below.

• 3 R’s ( Reduce, Reuse & Recycle)

• Rain water harvesting scheme.

• GWTS (Grey water treatment scheme)

• Installation of STP plant withinOrganization.

• ZERO LIQUID DISCHARGE SCHEME (ZLD included in ETP’s)

In this article we shall discuss overall working, challenges, saving & present innovations in the field of ZLD.

Process Description:

Recently we also introduce ZLD in our existing ETP system. Initially RO rejected is been diluted with fresh water & then further use in our system. This process requires amount of fresh water which itself not considered its solution. So we decided to adopt ZLD in our system. RO rejected having higher TDS values in range of 30000 to 40000 ppm which mainly consist of chlorides as a nacl, carbonate (CO-3) or bicarbonates (HCO-3) of calcium & magnesium ions (Hardness). RO

rejected firstly collected in a pit which is known as rejected pit. Feed from that pit feed to MEE (Multiple effort evaporators)

In Multiple effort evaporators Feed is concentrated is gravity to 1.3 from 1.0 & vapor generated is further recovered to the system & steam condensate is also recovered. Feed is generally heated with Low pressure steam of 3 kg/cm2 of pressure.

Feed which is concentrated in MEE is firstly collected & feed to ATFD which is again steam consumption Dryer & further salt is recovery which mainly consist of nacl, ca, mg,so4- ions & recovered water is taken back to a system for further uses.

Uses

1. Vapors condensate recovered is mainly used in cooling water makeup stream

2. Can be used in DM water production

3. Used in internal water consumption of plants

4. Steam condensate is used as feed for boiler

CHALLENGES DURING ITS OPERATIONS

Feed used in multiple effect evaporators having high TDS value shows high scaling nature. With time we found scaling issuing inside falling film type evaporators & thus product flow rate (vapor condensate) reduces down. Vice versa Steam requirement for same also increases.

So in every 6 months either JET cleaning of tubes are required. Acid (Nitric acid) circulation would also help in reduce down the scale formation.

The sludge generated through ATFD is another challenge to handle & requirement of skilled manpower to run a plant.

Requirement of Steam and auxiliary power for pumps, blower & agitator & cooling water for condensers & PHE would put extra burden for industries.

To install a ZLD in a plant itself contains high CAPEX which may not be suitable for Small manufacturing industries (SMEs)

MEEs require a high amount of energy in the form of coal or natural gas to produce steam. On average, it takes 300 kilograms of steam to treat 1,000 litres of effluent water. A kg of steam from piped natural gas (PNG) costs Rs 3.60[2]. Hence, just the fuel cost required to operate MEE is about Rs 1.20 per litre of effluent water. But as per present scenario of water crises industries should bair the same for the sake of humanity & with time cost of water recover from ZLD will reduce down.

NEW HOPE AS ALTERNATIVES OF MEE/ATFDS:

New technological developments in the membrane distillation technology, possibilities have emerged of significant reductions in operating costs as well as carbon emissions of ZLDs. Membrane distillation (MD) is an advanced form of

membrane-assisted MEE.

An MD system is powered by hot water instead of steam, so it can be powered by commonly used solar thermal collectors, thereby reducing the need of boilers (that will only be used during monsoon, when the solar option is limited.

MD system is developed by student of IIT Guwati& currently is under pilot level. In April 2016 a report was submitted by Industrial Pollution Prevention Group Centre for Environment Education, Ahmedabad, where it was concluded that “The concept of establishment of ZLD is good but it cannot be generalized and implemented hastily and uniformly over the entire country as it is very sophisticated, expensive, requires skilled manpower, consumes more power and emits more carbon leading to global warming. Further it also requires high operation and maintenance price for its execution and running”.