By Dr. AV Singh – Chief Sustainability Officer, Bajaj Power Group of Companies

Water, a substance composed of the chemical elements hydrogen and oxygen and existing in gaseous, liquid, and solid states. It is one of the most plentiful and essential of compounds. A tasteless and odourless liquid at room temperature, it has the important ability to dissolve many other substances. Indeed, the versatility of water as a solvent is essential to living organisms. We are living at watery planet. Very huge quantity of water exists on, in, and above our planet. About 71 percent of the Earth’s surface is water[1]covered, and the oceans hold about 96.5 percent of all Earth’s water. Water also exists in the air as water vapour, in rivers and lakes, in icecaps and glaciers, in the ground as soil moisture and in aquifers, and even in you and your pets. Water is never sitting still. Thanks to the water cycle, our planet’s water supply is constantly moving from one place to another and from one form to another. Things would get pretty stale without the water cycle. Water Pollution Water pollution can be defined as the presence of foreign substances or impurities (organic, inorganic, biological & radioactive) in such concentration which lowers the quality of water and makes it unfit to use. In other words, we can say that when any organic or inorganic substances get dissolved in water (water bodies like river, lake, and pond or in aquifers) and deteriorate the quality of water is known as water pollution. We can also define water pollution that “any changes in physicochemical characteristics of water which has a harmful effect on living organisms” is water pollution. Water pollution effects, both human health and aquatic life and causes many harmful diseases like Dysentry, Arsenicosis, polio, Eye infection, Cholera, Diarrhoea, Jaundice, Cancer, etc. The substances which are responsible for pollution are known as pollutants. These are found in water in suspended, colloidal and dissolved or in ionic form. The characteristics of pollutants depend on the source of pollution, it varies, and every industry has different pollution potential. The pollutants from the food or beverage manufacturing industry will always differ in comparison to the chemical manufacturing industry. So we can’t use the same treatment technology for all industries, it will change according to industryand its production process. It is necessary to collect the data related to the production process and effluent quality before finalizing the treatment scheme. There are two main sources of water pollution, these are: Point Source: The sources which can be identified at a single point are known are point source. The effluent discharge from any industry & domestic effluent through regular channels are the point sources. We can easily minimize the water pollution caused by the point source through collection and treatment. Diffused Source: The sources which cannot be identified easily are known as the diffused source. In diffused sources, the pollutants are found scattered on the ground ultimately reach to the water bodies and cause pollution.

Types of Water Pollution Natural Process: The natural process is mainly when decomposed organic waste like biomass or kitchen waste and dead animals added to water. It changes the quality of water and decreases the Dissolve Oxygen level which leads to an increase in the Chemical Oxygen Demand & Bio-Chemical Oxygen Demand.

Anthropogenic Process: The main sources are industrial effluent & domestic sewage. Agricultural run-off is also a big source for water pollution. The farmers are using lots of pesticides, herbicides & chemical fertilizer in their agricultural fields. These chemicals also cause water pollution when they go down and mixed with groundwater or mixed with surface water stream by runoff. Classification of Water pollutants There are lots of uses of water in our daily life like in bathrooms, laundry, in the kitchen, cleaning of floor and washing of vehicles, etc. On the other hand, industries also use a huge quantity of water for production, cooling & washing purposes. After uses the water gets polluted/contaminated by the organic or inorganic pollutants and no more usable. The pollutant responsible for water pollution can be classified into the following categories[1]Suspended Matter Industrial and domestic both effluents contain suspended particles in the form of organic or inorganic particles or of immiscible liquid (oil & grease). These particles are responsible for the turbidity of water.

The suspended matter has the following effects: The suspended matter reduces the light8 penetration in water bodies which inhibits the photosynthetic activities in aquatic vegetation. These provide the adsorption sites for8 harmful chemicals or biological organisms which may adversely affect the flora & fauna of water bodies. The settling ability of suspended matter also8 cause a harmful effect in water bodies it reduces the capacity of water bodies which leads to the degradation of that water body. The organic matter present in suspended8 is also responsible for the reduction in DO level.

Thermal Discharge The maximum industries especially power plant are using water for cooling of steam, equipment & machinery, during this process the water gain temperature and become unfit for further use. If industries discharge this water in any water body then it has a deleterious effect. The rise in temperature of water to such extends which is harmful to aquatic life is known as water pollution. The effects of thermal discharge are as under: The biological activities increase with the8 increase in temperature ( It doubles with an increase degree centigrade) Some aquatic organisms like cold water8 fishes die due to an increase in temperature. It reduces the oxygen dissolve rate in the8 water body which resulting in decreased Dissolved Oxygen levels. Low DO levels coupled with high temperature result in increasing the metabolic activity of micro[1]organisms thereby resulting in the reduction in the availability of oxygen leading to anaerobic conditions. It increases the algal growth which may8 become a problem for the aquatic ecosystem.

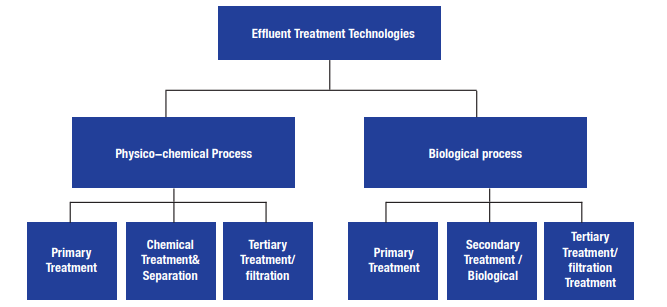

Pathogens Domestic sewage and industrial wastewater especially tanning industries, slaughterhouses, and hospital wastewater contains pathogens. Pathogens are the microorganisms that are capable to infect and transfer diseases to humans and animals. Microbes like bacteria, viruses, protozoa, and some helminths are some pathogens found in wastewater. These pathogens have an ability to survive in adverse conditions in water by forming cyst, egg, etc. and are capable of causing infection when the favorable season comes. Some impacts of these pathogens are: Cholera, typhoid, gastrointestinal disorder, poliomyelitis, hepatitis, dysentery, and some other viral infections are water-borne diseases. Natural Organic Pollutants The organics which reduce the dissolved oxygen in any aquatic system are natural organic pollutants. The organic pollutants are found in sewage & industrial effluent like sugar mills, distilleries, paper mills, slaughterhouses & food processing industries. The Dissolve oxygen is a necessity of aquatic life when organic pollutants enter any stream the aerobic bacteria start digestion and consume the DO. This phenomenon reduces the DO level in that stream and if the process continued the condition becomes septic. During day time the photosynthetic activities increase the DO level but in the night the respiration is being done by the aquatic flora & fauna which leads to reduce DO level. If the oxygen demand exceeds and dissolves oxygen level falls, it means the water body gets polluted. Synthetic Organic Pollutants The detergents, pesticides & fertilizers are examples of synthetic organic pollutants. Inorganic pollutants These are the heavy metals, alkali and acids, the effluent of metal industry, electroplating industry, and battery manufacturing industries having the potential of inorganic pollutants. Oil & Grease Oil & grease comes from the leakage or spillage during the replacement/filling of oil & grease in the machinery which is used in industries. Some industries like food & beverage and hotel industries have a large potential of oil & grease pollution because they use a huge quantity of edible and it comes in the effluent during the washing of manufacturing equipment. Oil & grease are hazardous material, if oil and grease mixed into water bodies, it forms the oil layer on the surface of the water and reduces the light penetration into water and photosynthesis. It further hinders oxygen transfer from atmosphere to water and this leads to decrease dissolved oxygen level at the bottom of the water and adversely affects the survival of aquatic life. Radioactive substance Nuclear waste is produced from industries mainly mining & refineries industries, medical, scientific processes, etc. These industries wastewater may contain radioactive pollution. Sediments Sand, grit, silt, minerals and soil particles are known as sediments; they come to streams from surface runoff from the agricultural field and also with domestic and industrial effluents. The impacts of sediments are: Increase turbidity of water which reduces8 the light penetration in the water stream. Cause asphyxia in fishes.8 It reduces the water stream capacity.8 Effluent Treatment Technologies Introduction: Physical, chemical and biological processes are being used for the treatment of effluent for further utilization. Sewage Treatment: “Sewage is generated by residence, institution, and commercial and industrial establishments. It can be treated onsite at the point of which it is generated (e.g, septic tanks) or onsite package plants), Typically, sewage treatment is achieved by the initial physical separation of solids form the raw wastewater stream followed by the progressive conversion of dissolved biological matter into a solid Biological mass wring indigenous, water[1]borne bacteria once the biological mass is separated or removed, the treated water may undergo additional disinfections via chemical or physical processes. The final effluent can then be discharged or reintroduced back into a natural surface water body (Stream River) or other environment like irrigation etc. Industrial Effluent Treatment: “Industrial source of waste water often require specialized treatment processes.” Physico-chemical Process: Wastewater contains particles of different sizes which can be classified as dissolved (< 0.08 μm), colloidal (0.08 – 1 μm), supracolloidal (> 100 – 100 mm) and settleable (> 100 μm). The type of treatment selected depends on the size of particles present in the wastewater. In practice, treatment efficiency also depends on particle size. Solids of the size that are visible to the naked eye can be separated either by settling under the influence of gravity or by flotation (Dissolved Air Flotation), depending on the relative densities of solids and water. They may also be easily separated by filtration. However, very fine particles of a colloidal nature (called colloids, size < 1 μm) which have high stability are significant pollutants. The reason for this stability is that these particles have electrostatic surface charges of the same sign (usually negative). This means that repulsive Effluent Treatment Technologies Physico-chemical Process Primary Treatment Primary Treatment Chemical Treatment& Separation Secondary Treatment / Biological Tertiary Treatment/ filtration Tertiary Treatment/ filtration Treatment Biological forces are created between them, preventing their aggregation and subsequent settling. It has therefore proved impossible to separate them by settling or flotation. It is not possible to separate these solids by filtration because they pass through any filter. However, separation by physico-chemical treatments is possible. Physico-chemical treatment of wastewater focuses primarily on the separation of colloidal particles. This is achieved through the addition of chemicals (called coagulants and flocculants). These change the physical state of the colloids allowing them to remain in an indefinitely stable form and therefore form into particles or flocs with settling properties. Stages of the Physico-Chemical Process The physico-chemical process consists of coagulation, flocculation and sedimentation stages. However there may be configurations where all stages are carried out in the same unit. Coagulation: Derived from the Latin coagulare meaning driving together, coagulation refers to destabilization or neutralization of the negative charges contained in the wastewater by the addition of a coagulant applied during rapid mixing (which can vary from 250 – 1500 s-1) and a very short contact time (times ranging between 5 – 60 s). The quantity of coagulant applied during coagulation depends on the quality of water (domestic or industrial). In the case of domestic water, commonly used doses are < 50 mg/L, while for industrial water the dose is very variable. The most commonly used coagulants are ferric chloride, ferric sulfate, aluminum sulfate, aluminum polychloride, sodium aluminate mixtures of organic and inorganic compounds, lime and the more recently studied application of iron polychloride. Flocculation: This is derived from Latin floculare, referring to the formation of flocs and bridges. In this stage, previously formed flocs group together, increasing in volume and density, During the flocculation stage, chemicals referred to as flocculants are applied (assisted flocculation). These products allow flocs to come together and adhere, increasing their size and density. Flocculants can be classified by their nature (mineral or organic), their origin (synthetic or natural) or their electric charge (anionic, cationic or non-ionic). Organic flocculants of natural origin are derived from natural products such as alginates (seaweed extract), starches (plant grain extracts) and cellulose derivatives. Their effectiveness is relatively low. Those of synthetic origin are long chain macromolecules, soluble in water, formed by the association of simple synthetic monomers, some of which have electric charges or ionisable groups. For these reasons they are referred to as polyelectrolyte. These products are highly efficient and recommended concentrations are 0.05% -0.1% for solid products, 0.1% – 0.2% for liquid dispersion and 0.5% – 1.0% for liquids in solution. Applied in excess they may harm the flocculation process. Sedimentation or clarification: This is the stage of floc removal by solid – liquid separation. For this, low, medium and high rate settlers are commonly used. The rate is determined by the speed at which water and sludge are produced by the system. Other popular technologies to separate solids from liquids are DAF clarifiers, lamella settlers and more. Secondary treatment or biological treatments: Secondary wastewater treatment processes use microorganisms to biologically remove contaminants from wastewater. Secondary biological processes can be aerobic or anaerobic, each process utilizing a different type of bacterial community.This is done by using either aerobic or anaerobic treatment processes or both., Biodegradation and Biological Growth: Successful biological treatment depends on the development and maintenance of an appropriate, active, mixed microbial population in the system. This microbial population may be present as either a fixed film attached to some form of support medium, as in the trickling filter and rotating biological filter processes, or a suspended growth, as in activated sludge processes and anaerobic digestion. Organic waste matter is used as a food source by the microbial population in each of these treatment systems. In their life processes, these microorganisms use some of the organic matter in order to synthesize new cell material, and they obtain the energy from their synthesis and cell maintenance functions by degrading some of the organic matter to simple compounds. Thus, biological growth involves both cell synthesis and biodegradation processes.

Aerobic Biological Treatment Conventional methods of biological treatment can be classified as either fixed film or suspended growth processes. An outline of the main processes of each of these classifications is given below. Within each classification, the processes are discussed in their approximate order of development. Fixed film processes Fixed film treatment involves establishing a microbial culture on a fixed medium and having the wastewater contacting the organisms by flowing past. Some fixed film processes are as under: Trickling filter: The trickling filter (c 1900) – also called a percolating filter and bacteria bed – consists of a bed of suitable coarse porous media on which grows a biological slime consisting mainly of bacteria, and on which graze various forms of worms and larvae which help to keep the slime active (Fig. 5.2b). Settled sewage is distributed over the surface of the medium and, as it flows down through the bed, the fine suspended and dissolved organic matter is absorbed by the biological film. Oxygen to sustain aerobic biological oxidation is provided by air which circulates through the bed. Clogging of the interstices within the filter bed as the bacteria grow, is usually prevented by portions of the film washed out of the bed by the wastewater flow. This material, which constitutes the net increase in biomass in the system and which would otherwise contribute high BOD and SS concentrations to the effluent, is the removed in final sedimentation tanks (known as ‘humus for further treatment prior to disposal. It is difficult to obtain an equal adequate measure of the active mass of biological solids in a trickling filter. Although the total surface area of the medium gives some indication of the possible areas on which the biomass could grow, both the actual thickness of the biomass and the percentage of it, which is active cannot be practically determined. Therefore, it is customary to take the volume of the medium as the most practical measure of microorganism activity in a trickling filter and so to express organic loading rate in terms of the daily mass of BOD applied per unit volume of filter medium (kg BOD/m3.d). The hydraulic loading rate per unit surface area of filter (m3/m2.d or kL/m2.d) is also important since it affects distribution of the flow over the surfaces of the medium, and hence the quality of contact between the applied organic matter and the active biomass. Rotating biological filter The rotating biological filter (c 1960) or RBF process is a recently-developed method of biological treatment which resembles the trickling filter process in that it uses a biological film grown on solid surfaces, but these are on a large number of closely spaced disc mounted on a shaft which rotates above a shallow basin profiled to the perimeter of the discs (Fig 5.2c). Approximately 40 per cent of the surface of each disc is submerged in the settled sewage flowing through the trough at any time. The shaft slowly rotates, alternately exposing the biological film absorbs organic matter and then, during contact with the atmosphere, it absorbs oxygen, so enabling aerobic oxidation to proceed. The net growth of biomass is washed off the surfaces of the discs and must be removed in final sedimentation tanks before discharge. Organic loading, as noted earlier, in this case is measured in terms of daily mass of BOD applied per unit surface area of disc (g BOD/m2.d).

Submerged Aerated Fixed Films (SAFF) The Submerged Aerobic Fixed Film (SAFF) process uses support media to retain an active biomass to reduce the influent BOD Levels. Tubular diffusers are used with the SAFF media giving a good air dispersal and low level of blockage due to growth of biological film. SAFF reactor is a type of aerobic attached growth treatment process. Small foot print area, stable process, lesser sludge production and modular installations are the key features of SAFF process. Essentially SAFF system is a hybrid reactor where attached growth and suspended growth activity takes place simultaneously. Submerged Aerated Fixed Films (SAFF) technology is a process used to reduce the organic loading of waste water, and in doing so will reduce the Biological Oxygen Demand (BOD) and a significant quantity of Suspended Solids (SS) which if otherwise untreated would contaminate river and sea outfalls, in other words it is used to substantially improve effluent discharge quality. As with traditional sewage treatment, Submerged Aerated Fixed Films Technology too uses three stages of dealing with commercial and residential sewage / waste water. Suspended growth process Suspended growth treatment systems freely suspend microorganisms in water. They use biological treatment processes in which microorganisms are maintained in suspension within the liquid. In suspended growth treatment systems, microorganisms convert the organic matter or other constituents in the wastewater into gases and cell tissue. The most common type of aerobic system is the suspended growth treatment system. Suspended growth technologies are conventional activated sludge treatment systems that use various process modes, ranging from conventional, extended aeration, contact stabilization, sequencing batch, and single sludge, which are available for polishing anaerobically treated effluents. A water treatment system used with suspended growth treatment systems can apply to industrial plants, heating and cooling systems, cooling tower systems, steam systems, and domestic water supplies and swimming pools. A wastewater treatment system is an essential component of effluent distribution systems. These suspended growth treatment systems deliver wastewater to soil infiltrative surfaces either by gravity or by pressure distribution. Residuals are the by[1]products of a wastewater treatment process, including sludge and septage. Polymers are used for industrial water treatment as scale inhibitors in stressed cooling water. They do not contain phosphorous, inhibit the deposition of calcium carbonate and other low soluble salts, and provide good activity over a wide pH range. Suspended growth treatment systems, such as biological treatment of water, involve the use of naturally occurring microorganisms in the surface water to improve water quality. Under optimum conditions, the organisms break down material in the water and improve the water quality. Natural suspended growth treatment systems, such as wastewater biological treatment, can be used for organic wastewaters such as municipal sewage and tend to be lower in cost for operation and maintenance. Although such processes tend to be land-intensive when compared to conventional biological processes, they are often more effective in removing pathogens and do so reliably and continuously when properly designed. Wastewater treatment equipment can be categorized as screening and conveying equipment, clarification and suspended solids removal equipment, aeration and biological treatment equipment, and tertiary treatment and disinfection equipment. 2.1.15. Activated Sludge processes: The basic activated-sludge process consists of aerating and agitating the effluent in the presence of a flocculated suspension of micro-organisms on particulate organic matter – the activated sludge. This process was first reported. By Arden and lockett (1914) and is now the most widely used biological treatment process for both domestic and industrial wastewaters. The raw effluent enters a primary sedimentation tank effiuent passes to a second vassel , which can be of a variety of designs, into which air or oxygen is injected by bubble diffusers, paddles, stirrers, surface aerators etc. vigorous agitation is used to ensure that the effluent and oxygen are in contact with the activated sludge. After a predetermined residence time of several hours, the effluent passes to a second sedimentation tank to remove the flocculated solids. Sedimentation tank to remove the flocculated solids. Part of the sludge from the settlement tank is recycled to the aeration tank to maintain the biological activity. The overflow obtained from the settlement tank should be of a 20:30 standard or better and be suitable for discharge to inland waters. The excess sludge is dewatered and dried, to inland waters. The excess sludge is dewatered and dried, to be sold as a fertilizer, incinerated or landfilled. In convention activated sludge processes, organic loading rates are 0.5-1.5 kg BOD m-3 day[1]1 with hydraulic retention times of 5-14 hours depending on the nature of the wastewater, giving BOD reduction of 90-95%. High-rate activated-sludge processes can be used as a partial treatment for strong wastes prior to further treatment or discharge to a sewer and are widely used in the food processing and dairy industries. The organic loading rate is 1.5-3.5kg BOD m-3 day –1, and with hydraulic retention times of only 1-2 hours, BOD reductions of 60-70% are possible (Gray 1989). A number of modification of the basic process can be used to improve treatment efficiency, or for a more specific purpose such as dentitrification (Winkler and Thomas, 1978: Gray 1989). Tapered aeration and stepped feed aeration are used to balance oxygen demand (which is greatest at the point of wastewater mand (which is greatest at the point of wastewater entry to the aeration basin) with the amount of oxygen supplied. Contact stabilization exploits bio sorption processes and thereby allows considerable reduction in basic capacity (~50%) for a given wastewater throughput. Denitrification (the biological reduction of nitrate to nitrite to nitrite and on to nitrogen gas under anoxic conditions) can be accomplished in an activated-sludge plant when the first part of the basic is not aerated In advanced activated –sludge systems the amount of dissolved oxygen available for biological activity is increased to improve treatment rate. One vessel of this type is the ‘Deep Shaft; (Hemming et al,. 1977), which is quite distinctive from the other the other aeration tanks and has been developed from the ICI plo SCP process (Taylor and senior, 1970). The deep shaft’ consists of a shaft 50 to 150 m deep, and separated into a down- flow section (down -corner) and anup-flow section (riser). The shaft may be 0.5-10 m diameter, depending upon capacity. Fresh effluent is fed into the top of the “Deep Shaft” and air is injected into the down flow sections at the sufficient depth to make the liquid circulate at 1-2 m s –1. The driving force for starting up, circulation is created by the difference in density (due to air bubble volume) between the riser and down—flow sections. For starting up, circulation of liquid is stimulated by injecting air at the same depth in to the riser. Air injection is that gradually all transferred to the air injection point in the down corner. Because of the pressure created in the down corner, oxygen transfer rates of 10 kg O2 m-3 h-1 can be achieved and bubbles contact time of 3- 5 minuts are possible instead of 15 seconds in diffused air systems. BOD removal rates of 90% are achievable at organic loading of 3.7-6.6 kg BOD m-3 day-1 at hydrolic retention times of 1.17-1.75 hours (Gray 1981) .sludge production was found to be much less than that for conventional sewage treatment processes. Two types of pure oxygen systems have also been develop to increase the rate of oxygen transfer. Closed systems which operate in oxygen–8 rich atmosphere and, Open systems employing fine bubble8 diffusers. Water Conservation The consumptive uses of freshwater from agriculture, industry and domestic sector place the greatest pressures on natural systems, both in quantity (withdrawals) and quality (impact of wastewater discharges). After agriculture, the two major users of water for development are industry and energy, which are transforming the patterns of water use in emerging market economies. Water and energy share the same drivers: demographic, economic, social and technological processes. Importance of Water Conservation Optimisation of water use by industries is important because it can lower water withdrawals from local water sources thus increasing water availability and improving community relations, increasing productivity per water input, lowering wastewater discharges and their pollutant load, reducing thermal energy consumption and, potentially, processing cost. Most industries generate pollutants as by[1]products of their producing activities, the major pollutants being nutrients, pathogens, heavy metals, organic and inorganic chemicals, oil sediments and heat. Heat as a thermal pollutant occurs if the water discharges of the industry change the ambient temperature of the water body. As water temperature increases, the amount of dissolved oxygen in the water decreases. Low oxygen levels in water bodies can be harmful to aquatic creatures. Temperature changes of just one degree can trigger subtle changes in the biology of aquatic organisms, causing them to change their metabolism or plant growth. How to optimize the water uses: Simplest way is to Educate Employees and Set Up a Water Conservation Programme. Build understanding among employees and co-workers about the importance of water conservation. Make them aware of water scarcity issues and the impact of water conservation practices. Educate employees so that they will be able to identify problems and innovate solutions to reduce water use within the company.The most important is the engagement of employees in problem[1]solving to reduce water usage. Assessment of Current Water Use: It is often useful to constitute a water audit8 team to audit the water. Use the information gathered through the assessment process to develop water reduction goals. See implementation support tools for more information on how to implement specific measures. Installation of water meters at different8 location or equipment to measure the quantity of water uses. Calculate average water use by department8 or process. Rank processes/departments by water use to determine where to focus conservation goals. Regular survey plant production areas to8 determine, where water is wasted or could be reused. Some typical operational changes for8 reducing water consumption at the operational level are developing a inspection programme for piping and hoses, reducing water consumption for cleaning (including switching to dry technologies) and finding multiple uses for water. In order for operational changes to be successful, the changes must be thoroughly planned, well implemented and followed by evaluating and monitoring activities to ensure sustainability in the long term. If the average water use (base level) is8 measured for all operational activities separately, the identification of leaks is simple: wherever water consumption rises above the base level, the presence of some form of water loss (e.g. a leak) is likely. Conduct regular inspection of equipment or areas where leaks could occur, like pipe-work joints, connections and fittings. Indications include dampness, rust marks or swelling boards. Significant leaks can often be detected by listening in the absence of other noises. Water use for cleaning can be further8 reduced if water from internal processes is used for cleaning. Depending on the water quality required for cleaning, this might require greywater treatment. Use brooms, squeegees and dry vacuum8 cleaners to clean surfaces before washing with water. Use washing equipment that has aerated8 spray nozzles with shut-off valves.