By Turbaashu Bhattacharya, Roserve Enviro Pvt Ltd

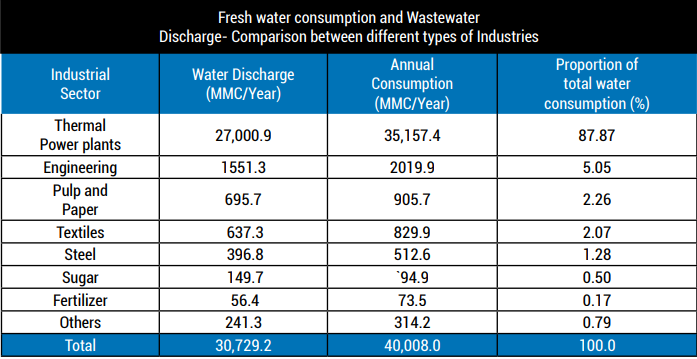

Wastewater reuse — recycling and reusing water from our sewerage systems — may prompt what is quite simply known as the “yuck” factor. People are naturally squeamish about the idea of reusing water that comes to sewage plant, even though it’s quite common. Wastewater reuse has been around for thousands of years. In India, Singapore, Mexico, and Spain, reused water can provide a valuable water source for key industries, reducing the demand on limited water resources. Power plants, refineries, mills, and factories, including, for instance, those in the auto industry, can use reused water. The need is great. Not only do some 4.2 billion people around the world lack access to safely managed sanitation services, but 80 percent of global wastewater is not adequately treated. As much as 36 percent of the global population lives in waterscarce areas, and water demand is expected to rise to 55 percent by 2050 amid rapid urbanization. The electric power production industry, comprising hydroelectric, nuclear, and coal and oil-fired power stations, account for 50% to 70% of industrial water use. Paper and pulp production, chemicals, mining and metal processing, and petroleum refining all use substantial amounts of water in their operations. The amount of water used in producing various goods and services is called water intensity. Manufacture of a pound of paper takes about 11,400 liters of water, while producing one car takes, on average, about 2,46,000 liters. A pound of aluminum takes about 7,57,000 liters of water to produce and a hamburger around 4,999 liters. Rather than a disposal liability, recycling and reusing industrial wastewater and sewage water onsite is now considered a smart business practice, one that helps companies become more profitable and efficient. The transport of wastewater to offsite facilities is very expensive. When industrial facilities recycle wastewater on-site for reuse in a variety of industrial processes, they are saving substantially on transportation as well as disposal and energy costs. Recycling and reusing wastewater is an economical path to meeting your industry’s large-scale water demands because, let’s face it, many, many industries are extremely water intensive.

Sustainability is a term which is heavily used but not necessarily well-understood. In simple terms, it is focused on meeting the needs of the present without compromising the ability of future generations to meet their needs. It has an economic, environmental, and social component.

Case Study – Automobile Industry At one of our client’s, an Automotive Industry biggie, their process generates around 300 Cubic meters of sewage wastewater. We came up with an idea to recycle this treated STP effluent and reuse it for non-potable applications such as washing, flushing, cleaning, gardening and for infrastructure applications. Following is the case study which shows how this Hybrid RO technology helps to achieve our targets and gives us a Sustainable Solution. Current ScenarioWastewater source – Sewage from Toilets, Wastewater from Canteen Quantity – 300 Cub. Meters per Day Fresh Water Cost – Rs. 60/ Cub. Meter Existing Treatment Facility – Basic Sewage Treatment Plant (STP) Application of Treated STP effluent – NO APPLICATIONS – Drain out to river Based on the last 6 months analysis reports and subsequent trials we have designed and installed 300 KLD Hybrid RO systems with 75% recovery. The treated water quality is better than the fresh water quality which can even be reused for the industrial applications in Utilities, Washing-Flushing etc. Present Scenario – Treatment System – Hybrid RO system Feed Quantity – 300 Cub. Meters per Day Permeate Quantity- 225 Cub. Meters per Day Sr. No. Treatment Parameters Recycled Water Costs (in Rs/Cum) Fresh water cost (in Rs/Cum) 1 Operational & Maintenance Cost 21 60 2 Manpower Cost 9 3 Electric Power Cost 10 4 Fixed Cost of Equipment (6yrs) 20 TOTAL 60 60 Cost After 6 Yrs. 40 66 Recovery Rate – 75% Following Table illustrates the breakup of treatment cost and comparison against the freshwater costApplications – Utilities- Cooling tower make up, Boiler feed water. Civil Infrastructure | Washing Auto Parts, Cars. Flushing & Gardening.

Water Analysis Reports: – Benefits under OPEX model – Roserve Enviro Pvt. Ltd. is a FinTech company which provides Solutions for Wastewater management using cutting edge Technology along with Innovative BOOT/BOO models viz., Built Own Operate & Transfer. We design the treatment system based on the quality and quantity of effluent and requirement of treated water quality. This system is specially designed for your applications. We are backed with the latest technology and expert Service teams with almost 30 years of experience across more than 1800 installations in India and the World. Roserve Enviro takes care of the entire system including Operations, Maintenance, manpower, health of system etc. We provide assurance for the service as well as treated water quality and quantity. Highlights of our Plug & Play Recycling Model v Ready to use equipment v Quick Mobilization v Pay per use model v Rental options on Zero Liquid Discharge v Flexible renting solutions along with shortterm rental options v Consistency in Quality & Quantity of treated water. v Less footprint area v Technologically upgradable with minimum increase in costs This Plug & Play Recycling model has been initiated by us to provide a strong foundation for the Automotive Industry to ensure they achieve their sustainability norms, while at the same time are able to manage their harmful effluent disposal impact on the environment.